Professional 600Kg Welding Positioner with Core Motor Engine & Bearing Components Versatile for Construction Industries.

Contact UsWhen choosing a 600kg positioner, the weight, diameter, length and eccentricity of the workpiece are key considerations. Generally speaking, if the weight of the workpiece is close to 600kg, it is necessary to ensure that the load capacity of the positioner can stably support the workpiece. For example, when the weight of the workpiece is about 550kg, the diameter is large, and the length is moderate, a standard model of 600kg positioner can be selected to ensure the stability of the workpiece during the welding process.

If the length of the workpiece is long, even if the weight is within 600kg, the offset of the center of gravity needs to be considered. For example, for a workpiece with a length of 3 meters and a weight of 400kg, due to the long length, the center of gravity may deviate from the center. In this case, a large positioner should be selected to prevent instability during the flipping and rotation process. .

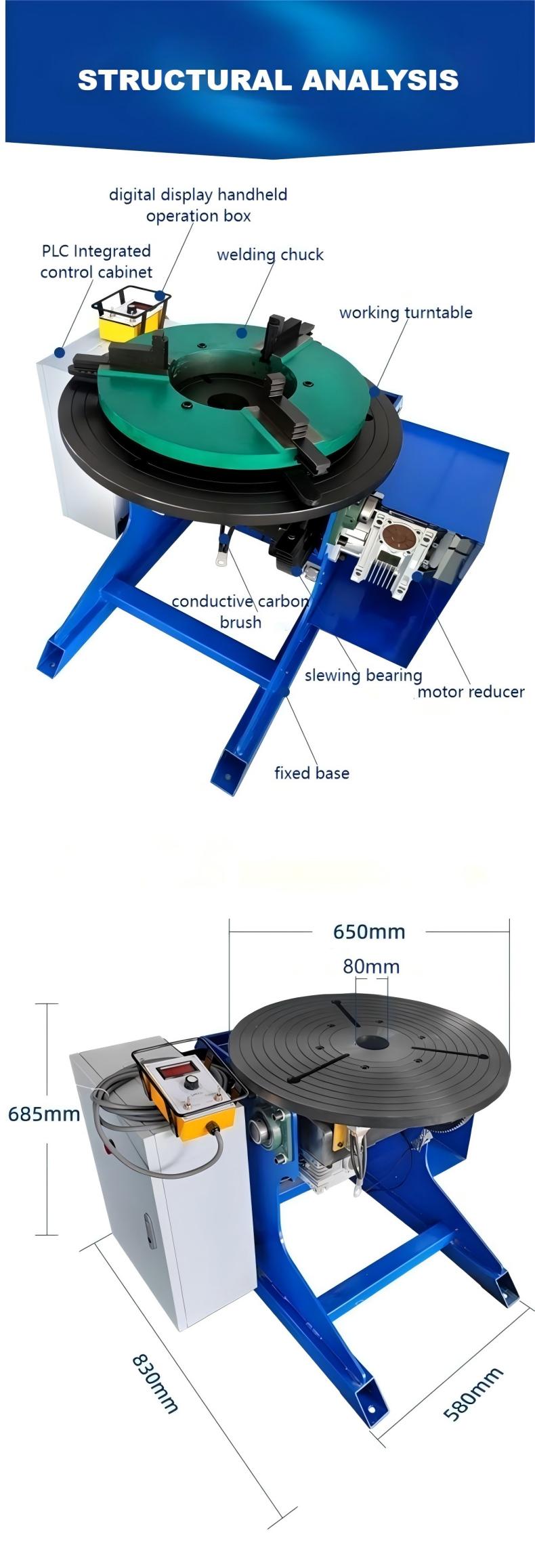

Regarding the eccentricity problem, when the workpiece is relatively light but the eccentricity is relatively large, a relatively large welding positioner should also be selected. Suppose a workpiece weighs 300kg, but the eccentricity reaches a certain level. In order to ensure stability and safety during the welding process, it is wise to choose a larger positioner. The 600kg positioner plays an important role in the circumferential seam welding of workpieces within 600kg. The AC variable frequency motor is used to drive the worm gear reducer to drive the large and small gears to rotate, thereby driving the table to rotate, and the flipping method is generally electric. During the circumferential seam welding process, the positioner can tilt and rotate the workpiece to place the weld seam in the optimal position for welding, such as horizontal or boat-shaped. The 600kg positioner can be used in conjunction with welding manipulators, robots, etc. to greatly improve the degree of welding automation. For example, welding robots can stabilize welding quality and improve welding efficiency in the welding market, but when faced with more complex workpieces, the flexibility of welding robots is limited. At this time, it is used in conjunction with a 600kg positioner to achieve flexible welding through the coordinated movement of the two.

YUNKANG Welding Supply is not only in the production and sale of rotary positioner, welding positioners, welding machines, turntables weld and welding rotators, we can also provide complete supply chain service for your purchase in China!

Sometimes you only need an idea or a function that needsto be implemented,and we can design it.

If you have already designed it yourself, but need a factorywith strong manufacturing capacity, YES, contact us!

If you not only buy equipment from YUNKANG, but alsobuy things from other suppliers, we can provide freeinspection service.